The safe and economical distribution of electrical power has been a constant challenge and this is the reason that a vast majority of electrical applications call for copper a material with superior electrical conductivity than all metals except silver combined with excellent corrosions resistance ductility strength and good process ability.

Copper bus tubes for electrical application.

Available in schedule 40 regular and schedule 80 thick wall thickness storm s copper bus tube is made of alloy 10200 ofhc oxygen free copper with reduced electrical resistance and enhanced ability to carry current.

1977 63 astm b 188 81.

Copper bus tubes for electrical application.

C102 copper is 99 95 pure copper contains essentially no oxygen.

The energy efficiency and copper motor rotor sections have moved to the new sustainable energy section.

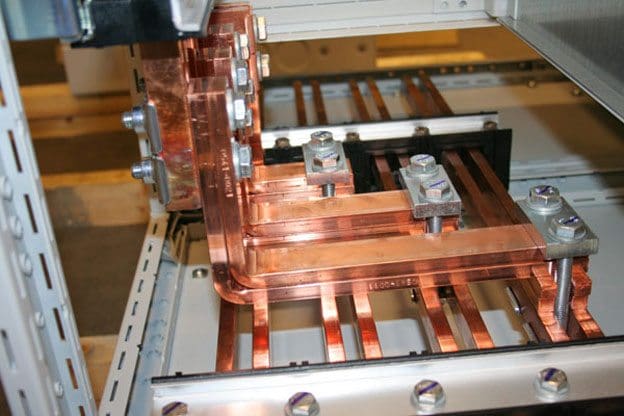

The system may have one or more joints to assure proper length and configuration and one or more take off points connected to end use equipment.

Manufactured to astm b188 02 with diameters ranging from 50 to 3 00 in 20 ft.

Copper alloy 102 has high conductivity at 101 and has exceptional ductility.

For hundreds of years copper has also been used as an architectural metal.

The bars may be exposed or enclosed.

The transmission and distribution system where.

Storm s equipment includes presses press breaks water jet laser and punching machines to produce materials processes and finished components engineered to meet standards required by as9100d and.

2871 part 2 72 c 101 near equivalent specification b s.

Inventories c10200 ofhc copper bus pipe which is sometimes referred to as bus tube.

This is a typical starting point for the proper engineering design of the bus for the specific application.

Copper bus tubes for electrical application as per b s.

The commonly accepted rule of thumb for initial sizing of high conductivity copper bus is.

Busbar systems refers to conductors that take the form of a bar or bars of copper conductor.

2871 part 2 72 c 101 near equivalent specification b s.

Some of the oldest examples of copper s use as an aesthetic structural metal include the doors of the precinct of amun re at karnak in egypt which dates back 3000 4000 years and the copper shingle roof atop sri lanka s 162 foot tall loha maha paya temple constructed in the third century b c.

3 000 amps per square inch for water cooled applications and 900 amps per square inch for air cooled applications.

1977 63 astm b 188 81 uses.