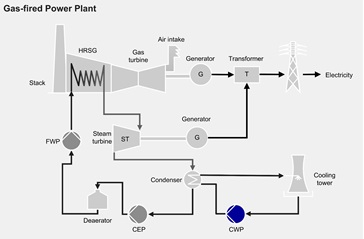

Cooling towers are typically used in large scale cooling operations such as power generation oil and gas refining and thermal power stations.

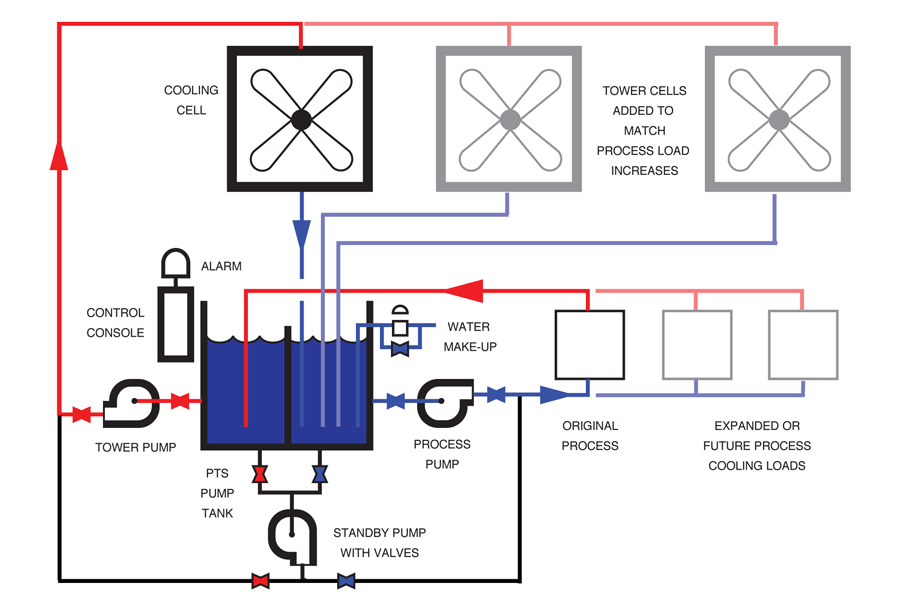

Cooling tower systems typically use pumps.

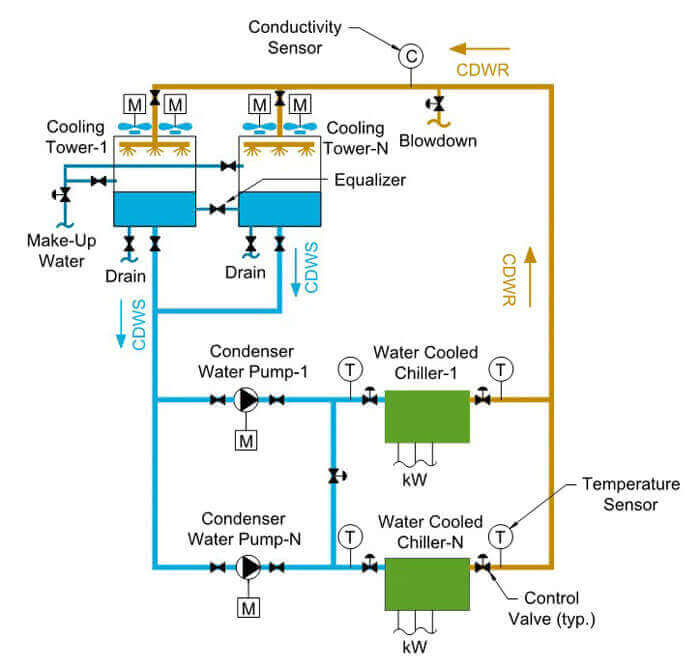

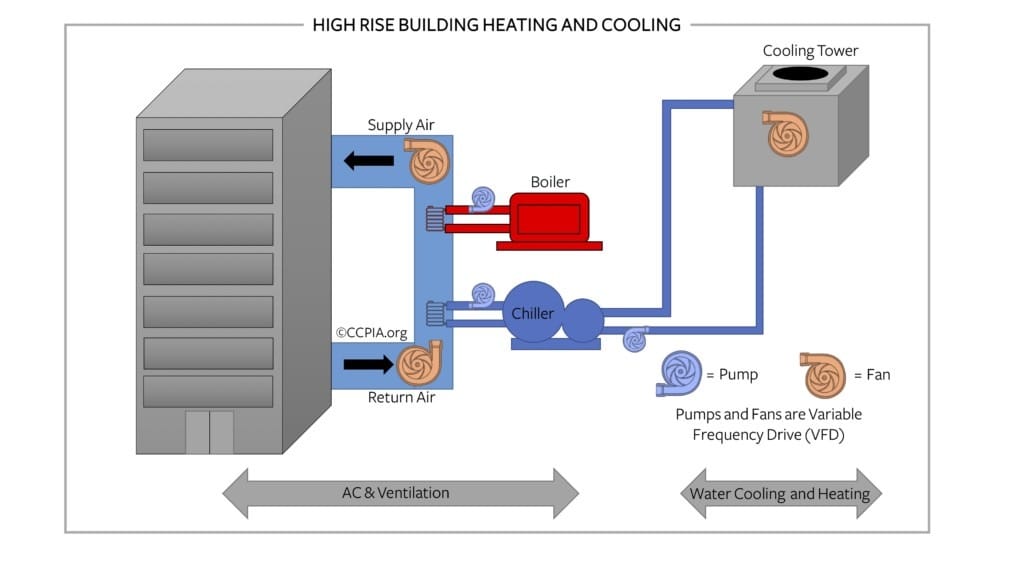

Chiller based systems typically offer a higher efficiency than vav systems and are also more practical for multi story buildings.

An open cooling tower is a place where a fire may occur during the off season when the tower components are dry and flammable such as for some and another wetting system may be an auxiliary pumping system that keeps the tower continuously wet whenever the weather is above freezing.

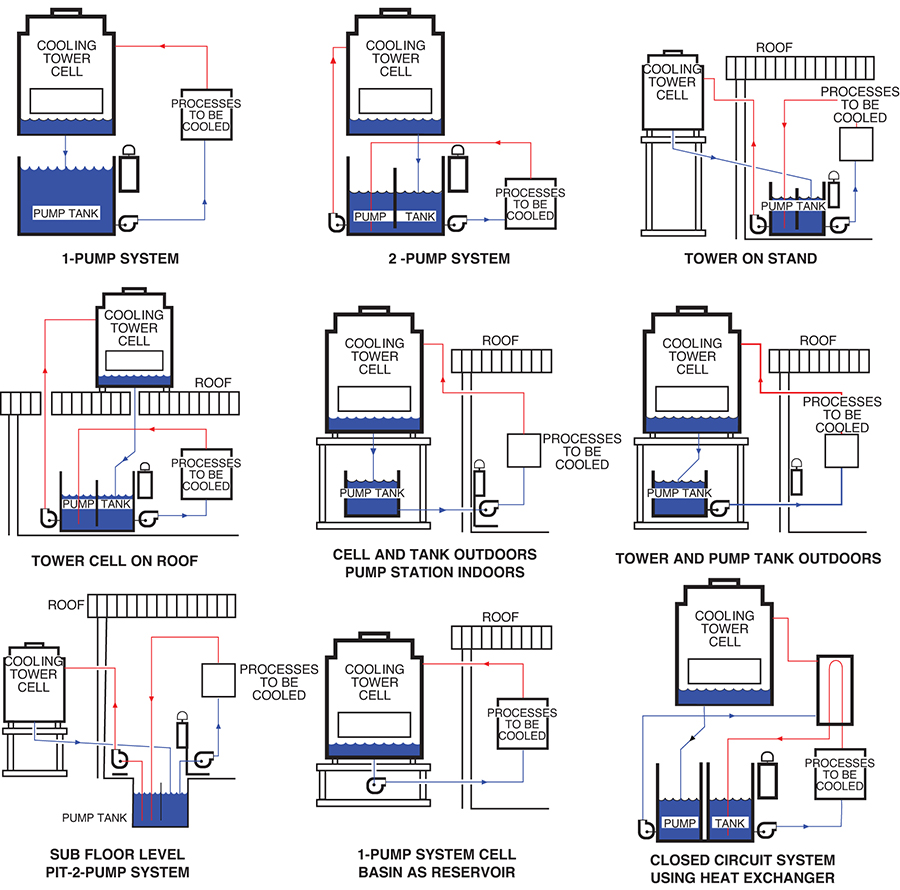

Static height not considered for pump selection in closed loop.

We also have odp motors available.

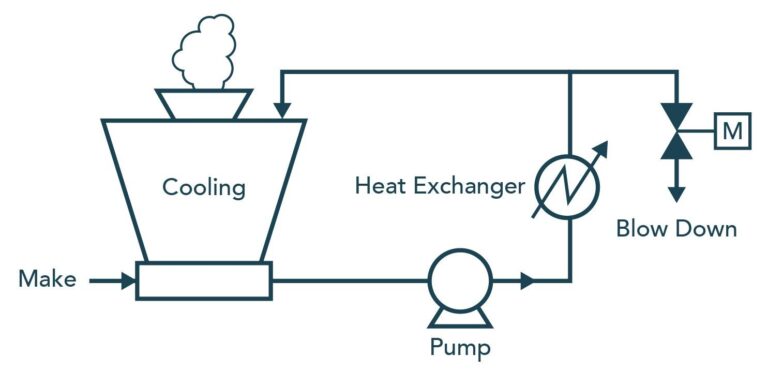

Cooling tower systems work by using water to extract waste heat from a system and ejecting it into the atmosphere primarily through evaporation.

These odp motors or open drip.

Water first passes through a heat exchanger where it absorbs heat.

We have tefc motor options available for outdoor use.

Has manufactured various models of fiberglass water cooling tower systems and related equipment for over 40 years.

Architects engineers and other professionals in the green construction industry can add great value to their professional record by becoming leed green associates and accredited professionals green buildings are a strong trend in the construction industry globally and professionals with leed credentials can gain a significant competitive advantage.

In areas with a hot climate large office buildings hospitals and schools typically use one or more cooling towers as part of their air conditioning systems.

Water source heat pump systems would also typically have a cooling tower but no chiller.

Rather than having several packaged rooftop units it is possible to consolidate the system into a single chiller and cooling tower and only the cooling tower has to be located outdoors or on the rooftop.

A water source heat pump system would also provide heat utilizing the.

The pumping head determination procedure for the open tower piping loop differs from the conventional closed.

Ranging from our small 3 ton to our largest 1500 ton the t 2 model is what sets cts apart from the rest.

This product line allows users to maintain higher levels of efficiency over a wider range of operating conditions.

Our cooling towers are second to none in quality and energy efficiency.

Cooling tower system replacement.

A system that is similar to a chilled water system is a water source heat pump system.

Flow friction loss h closed loop piping circuit.

Cts has a quality line of water pumps specially designed for our cooling towers.

Generally industrial cooling towers are much larger than hvac towers.

Open tower system pump head requirements.

Cooling tower pumping and piping.

One very important deciding factor on choosing a chiller or a cooling tower should be based on the required coolant temperature.

Hvac use of a cooling tower pairs the cooling tower with a water cooled chiller or water cooled condenser.