While onsite the cooling tower cleaning crew washes all hard surfaces with high pressure water including the cooling tower hot deck and the sump floor.

Cooling tower cleaning equipment.

Goodway cooling tower cleaning systems make ongoing maintenance fast and easy.

This prevents fouling problems that can be caused when sludge in the basin is transferred to the cooling water lines and heat exchangers in the process unit.

Order your cooling tower cleaning chemicals today.

In houston texas a regional laboratory for a leading environmental agency was having problems with dirty cooling tower water which lead to hvac loop system downtime and increased labor and maintenance costs.

We believe it is easier for our current clients to use us for both their water treatment needs and their cooling tower and other equipment cleaning renovation and replacement needs.

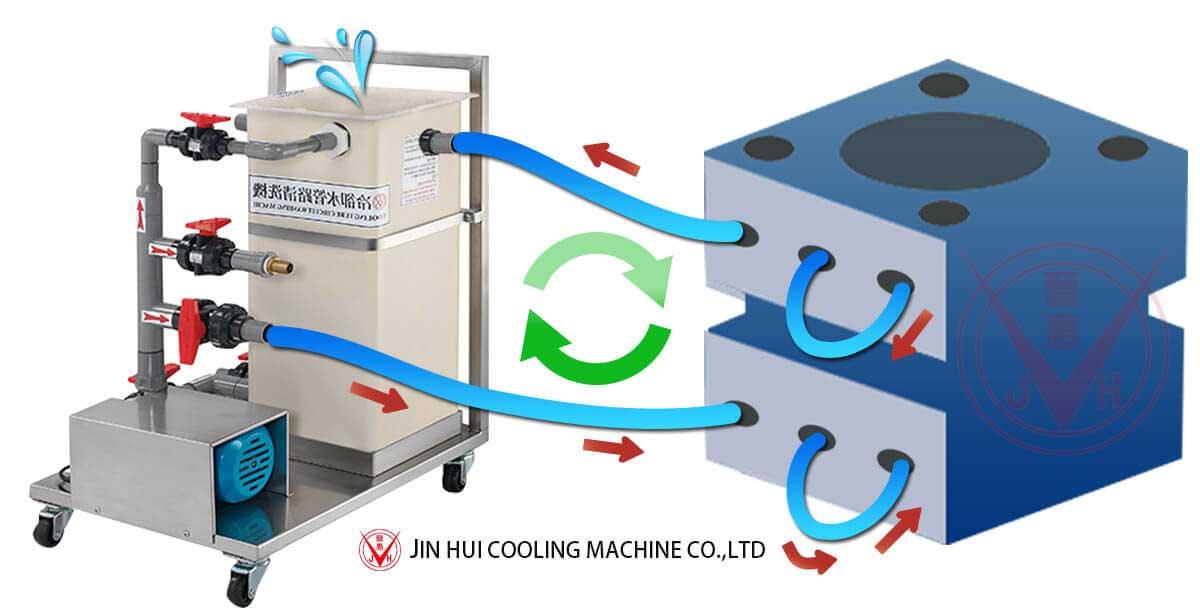

The diagram below shows a sludge removal system to clean the basin of a refinery cooling tower.

Cooling tower cleaning equipment.

Don t end up with a sick hvac system that can cause health issues and open up a litigation nightmare.

To clean a cooling tower you ll need to power down the fans wear protective gear identify dirty and clogged areas and kill disease causing bacteria from your cooling tower.

Downtime eliminated reduced maintenance costs on cooling tower basin cleaning.

Since 1999 hundreds of our clients have trusted us to save them money by extending the life of their equipment through cleaning education and renovation.

Before goodway common cooling tower cleaning methods that used fire hoses garden hoses or pressure washers were 3 day cleaning tasks that.

The cooling towers are disinfected with a biocide before the cleaning crew starts.

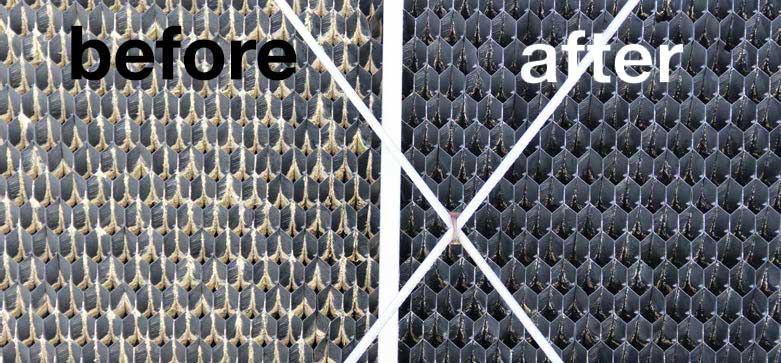

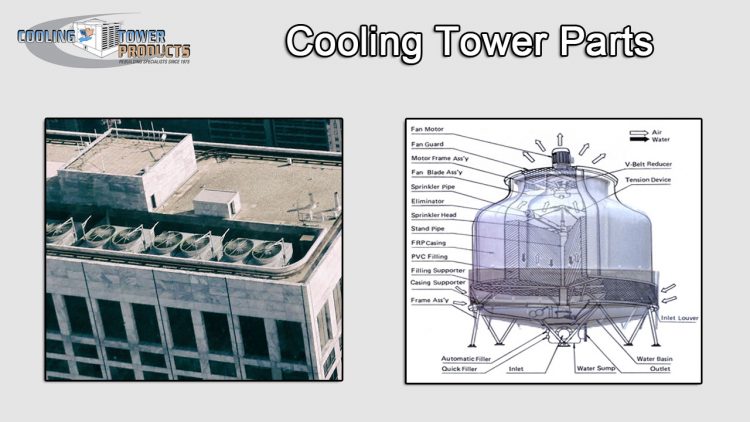

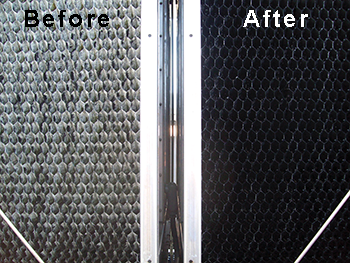

Scaling within a cooling tower can restrict the water distribution of spray nozzles reduce the water flow through the openings of a hot deck and restrict the airflow within the tower.

When it comes to cleaning cooling towers there isn t a great selection of effective equipment on the market with the exception of goodway s complete line of cooling tower maintenance solutions.

Cooling tower cleaning is made easy with rydlyme biodegradable descaler rydlyme is simply circulated through the cooling tower removing mineral and scale build up in a safe and timely manner.

Cooling towers are collection areas for mud sludge and bacteria.

However passivation or re passivation with pt1133 should be performed after the sanitization phase is completed.

If initial sanitization of the tower is required a 10 0 ppm free halogen as cl2 residual can be maintained in the system for up to 24 hours.