With starrco modular grow rooms you can add rooms modify the layout add a second floor or dismantle the entire commercial grow facility and move it to a new location where you can quickly reassemble it in a way that avoids the downtime and mess associated with conventional construction projects.

Commercial grow room design plans pdf.

The design team at innodez is involved in the commercial grow room design for cannabis and hemp facilities for medical industrial cultivation extraction manufacturing and retail purposes.

Whether the project is a new ground up building or a tenant improvement in an existing building we have the proper knowledge and experience to produce.

Building a cannabis cultivation facility.

Since there is great interest in becoming involved in cannabis.

Cannabis vertical grow system.

Large grow room design examples.

Another example is that they may not understand how to design a facility with clean room protocols because they have not operated in a regulated state 8.

By maximizing space.

8 x 8 grow tent setup and design.

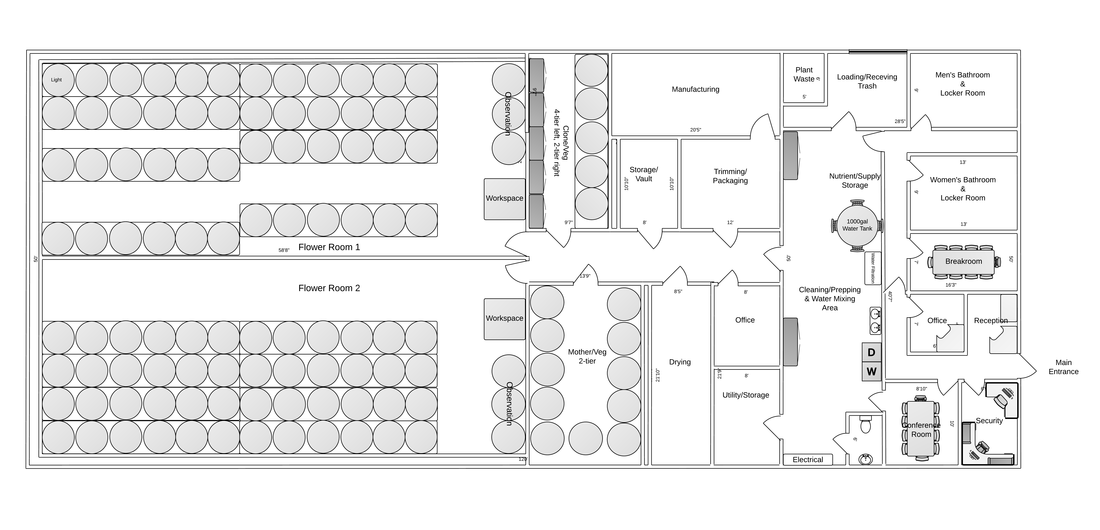

Commercial grow room design plans cannabis facility design.

If you are lucky enough to have a larger room to grow in you can get really creative with your set up.

Home ashrae oregon chapter.

There are a few key components to consider when designing a efficient and sustainable commercial grow room such as how much space is required how to water crops how to provide power and how to properly light the space.

Make sure your grow room designer has proven facilities under their belt.

The sky is the limit and you can have as few or as many tents as you d like.

We are going to show you some designs you can copy for your own room based off a 15 x 15 room.

How does a cleanroom adapt for a medical cannabis grow.

It starts with specialized containment rooms hvac air showers clean surfaces and contained lighting systems.

Growing commercial cannabis is no simple task so it s very important to understand from the beginning what the major costs and elements are for a successful facility design.

Thc design uses a closed loop process to produce its cannabis which recycles resources back into the growing system.

This fall peters plans to add a 250 000 watt solar array to help generate electricity for eco firma farms furthering his commitment to sourcing alternative energy for cultivation.

Grow room design construction.

We help optimize any commercial cannabis grow room design to produce consistent high quality products while also controlling costs and boosting yields.

Grow your yields and grow your profits.