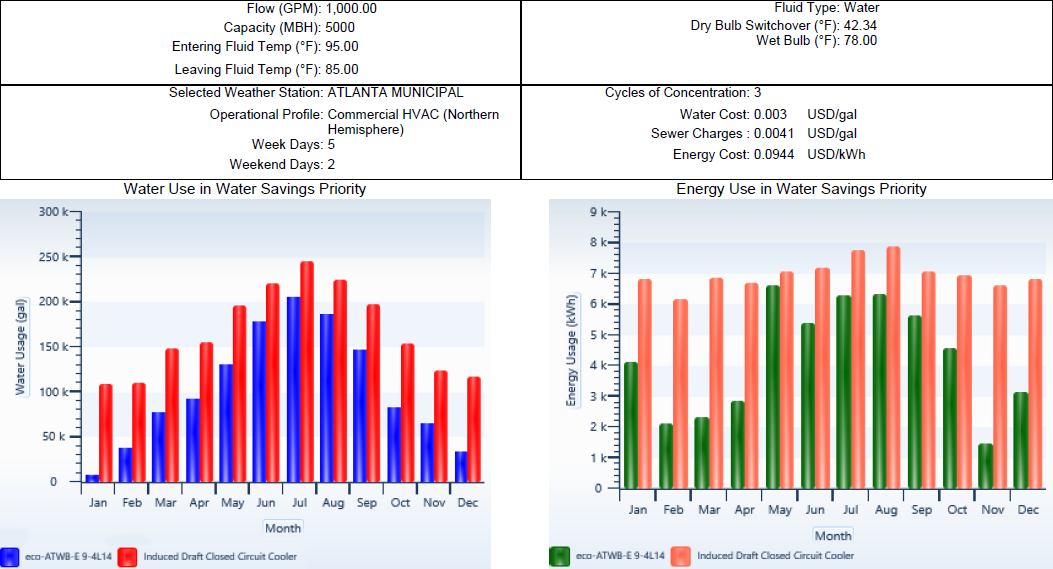

Bac leads the industry in the design and manufacturing of closed circuit cooling towers with the most efficient and cost effective units with both water and.

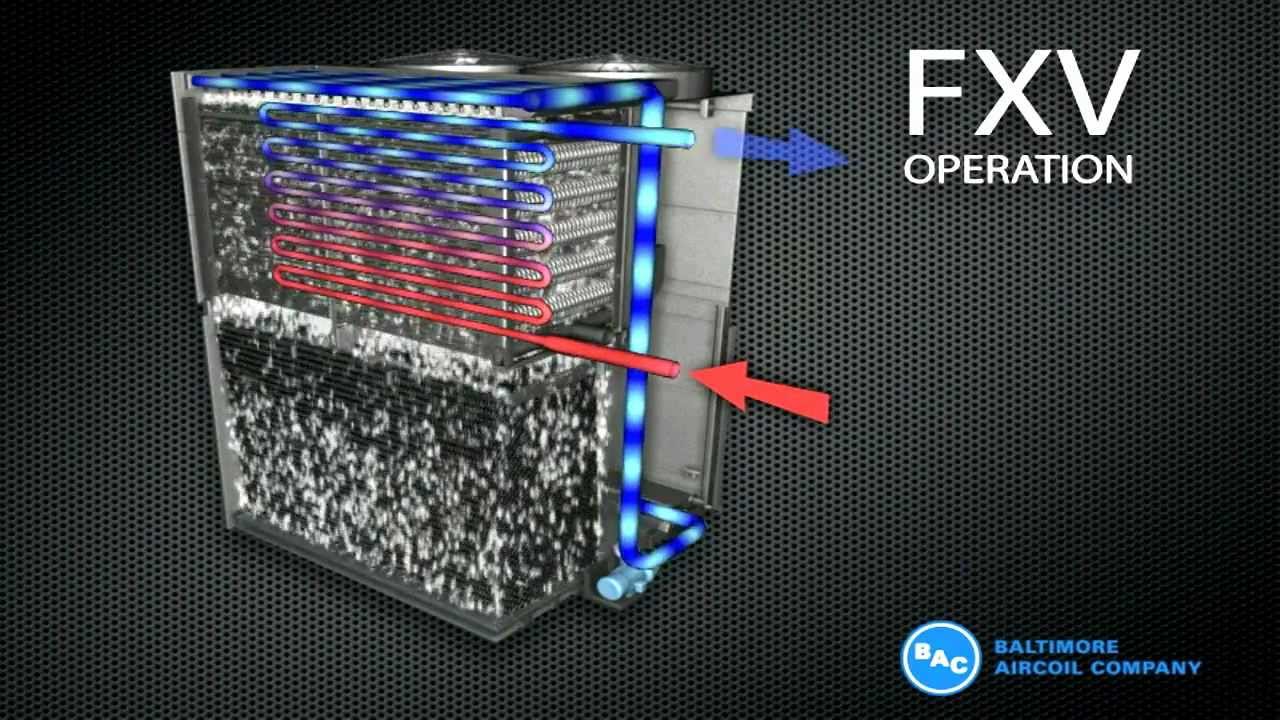

Closed circuit cooling tower sequence of operation.

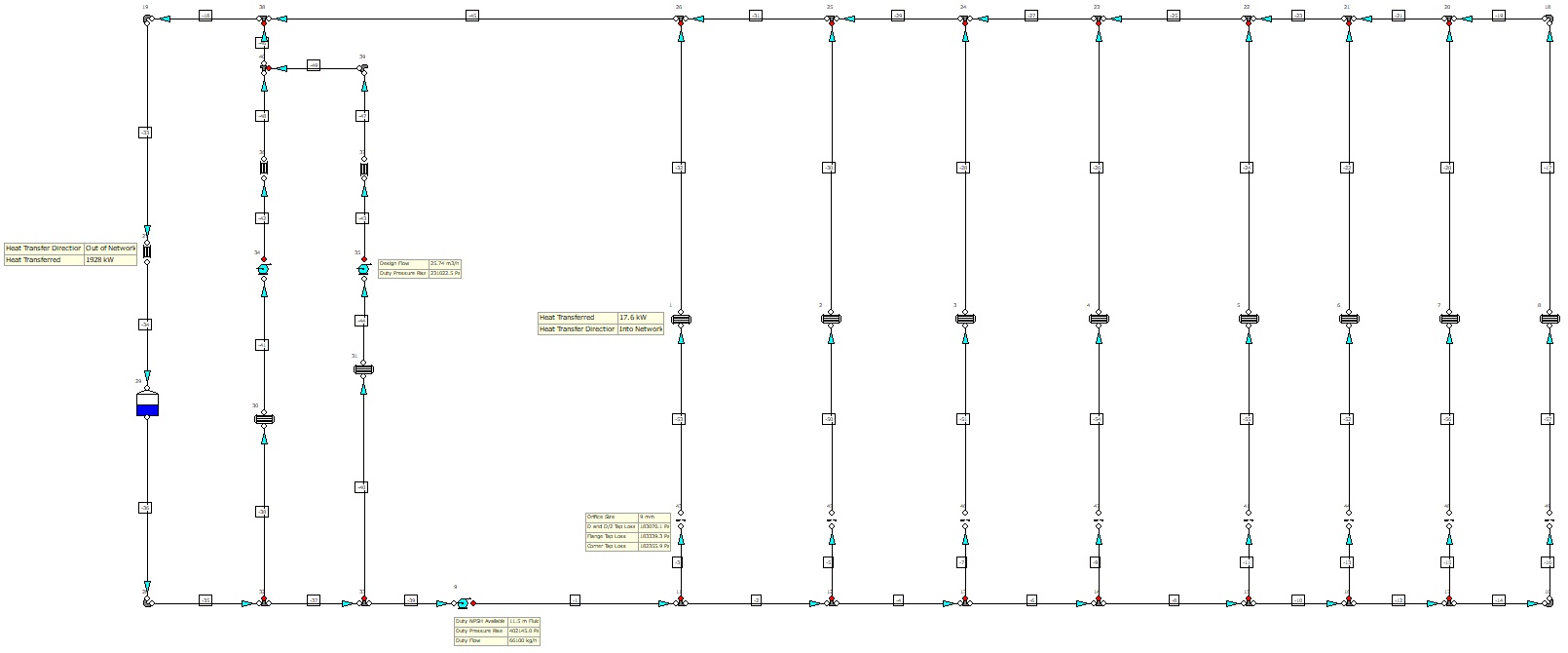

We may add some percent of the cooling water from the available water resources to the closed circuit cooling system and we can reduce the cooling tower size.

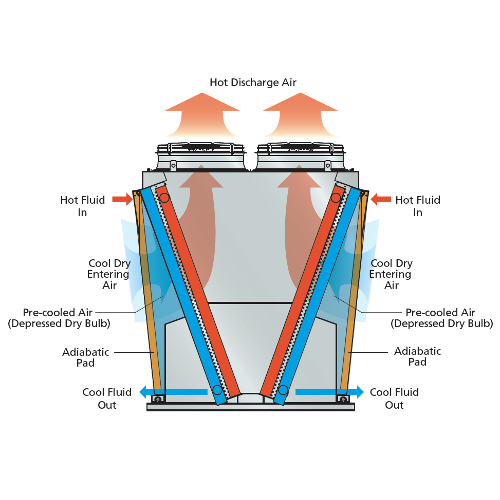

Such substantial depression of the air temperature results in a significant increase in dry cooling capacity and energy efficiency.

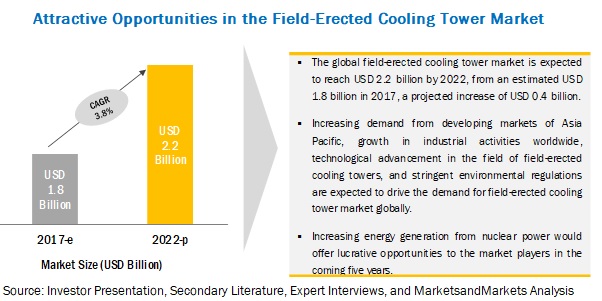

Baltimore aircoil is the leading global manufacturer of cooling towers closed circuit cooling towers evaporative condensers and ice thermal storage systems.

They extract heat to the atmosphere through evaporative cooling.

When the unit is in pre cooler mode water is evenly distributed over the highly efficient pre cooler pads.

The air is cooled to 1 3 f above the wet bulb temperature.

During the time of shortage of cold water supply we have to go forclosed circuit cooling tower.

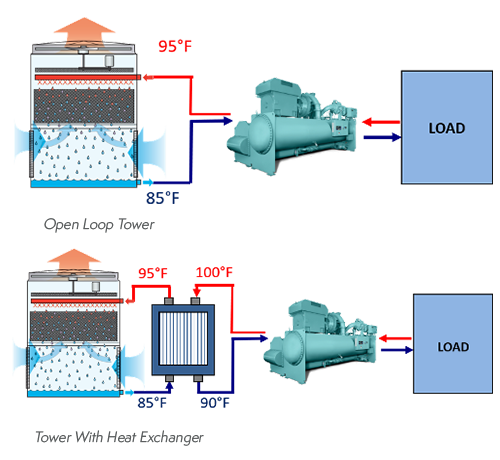

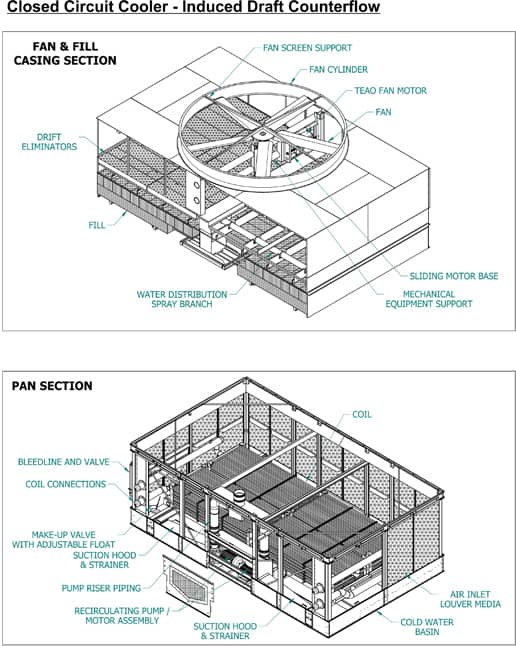

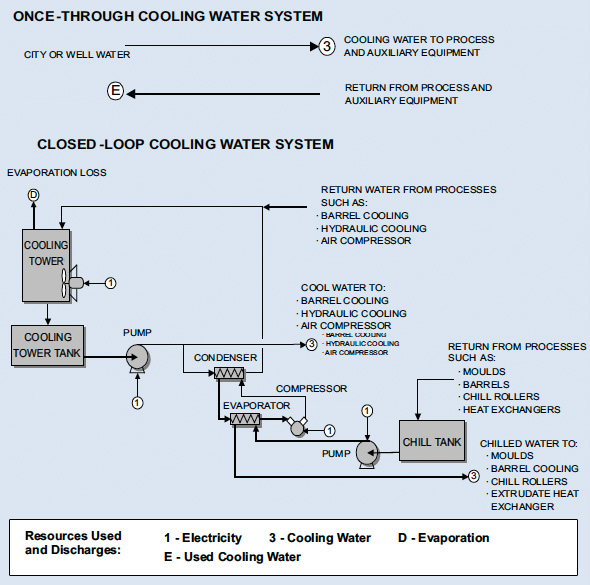

Closed circuit cooling towers operate in a manner similar to open cooling towers except that the heat load to be rejected is transferred from the process fluid the fluid being cooled to the ambient air through a heat exchange coil.

Cooling towers work on the principle of heat rejection.

The towers themselves are enclosed steady flow devices for cooling water by evaporation through direct contact with air.